16 Aug Industry 4.0: What does it bring to my company?

Revolution always involves a change in the way of making things, usually supported by a cause with hope of improvement. In this case, things are not different. What changes in this revolution is the way of working, the introduction of technology and smart machines in traditional industry. And, what about the cause? Well, Industry 4.0 is an opportunity to improve production processes in the construction, engineering or manufacturing industries, beside others.

Today, we are going to take a closer look at how it works, and the changes it brings to our companies.

What is Industry 4.0?.

Industry 4.0 or Smart Industry, makes reference to Fourth Industrial Revolution. This involves the digital transformation of industry, with the integration and digitalization of all the industrial processes that make up the value chain. It is characterized by adaptability, flexibility and efficiency that allows meeting the needs of customers in today’s market.

In short, Smart Industry uses digital technologies to react faster to market changes, offer more personalized products and increase operational efficiency.

Principles on which this new paradigm is based

![]() Interoperability. The ability to communicate between all systems in the factory. Corporate information systems, cyber-physical systems, robots, smart products, and people.

Interoperability. The ability to communicate between all systems in the factory. Corporate information systems, cyber-physical systems, robots, smart products, and people.

![]() Decentralization. Ability to design autonomous threads within the factory. It is about using cyber-physical elements that have the ability to make decisions autonomously.

Decentralization. Ability to design autonomous threads within the factory. It is about using cyber-physical elements that have the ability to make decisions autonomously.

![]() Virtualization. Be able to generate a virtual copy of the factory by collecting data and modelling industrial processes. This way, virtual plant models and simulation models can be obtained.

Virtualization. Be able to generate a virtual copy of the factory by collecting data and modelling industrial processes. This way, virtual plant models and simulation models can be obtained.

![]() Modularity and scalability. Flexibility and elasticity to adapt to the needs of industry and business at all times.

Modularity and scalability. Flexibility and elasticity to adapt to the needs of industry and business at all times.

![]() Real-time analytic. Ability to collect and analyse larg amounts of data that allow monitoring of process, control and optimisation. As a result, it is possible to facilitate any results and decisions arising from the process immediately and at every moment.

Real-time analytic. Ability to collect and analyse larg amounts of data that allow monitoring of process, control and optimisation. As a result, it is possible to facilitate any results and decisions arising from the process immediately and at every moment.

![]() Service orientation. The ability to transfer to the costumer the new value generated in form of new services or improved services through the operation on new disruptive business models.

Service orientation. The ability to transfer to the costumer the new value generated in form of new services or improved services through the operation on new disruptive business models.

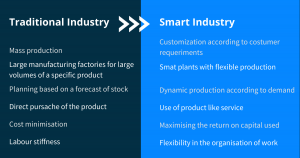

What changes do Smart Industry bring to the company?.

We can appreciate some differences between the production way in traditional industry in comparation with Smart Industry.

Besides this changes, we also can appreciate the many benefits that Industry 4.0 brings to our companies:

- Increased productivity and better management of resources.

- More efficient decision-making, based on real information.

- Optimal and integrated production processes.

- Increase flexibility to achieve massive, customized production in real time.

- Direct comunication between clients and organisations. It means that we will be able to get to know better about customers needs.

- Reduction of manufacturing time for new product designs and their marketing.

- Reduction of the percentage of defects in factories. This is because it will be possible to test the prototypes in a virtual way, and optimize the mounting chains.

FIWOO, your platform for Industry 4.0.

FIWOO is an IoT-Editor platform, based on FIWARE, that allows you to access, analyze and act on the data that your business brings and provides you the right tools to extract value. Improve production, reduce downtime, decrease service costs to your customers and get an holistic and unified vision of your company.

You can contact us for a free demo. Also, you can find more information about our platform or see some use cases in our Smart Industry page.

No Comments